As posted on the Facebook Monocoupe Aircraft Group:

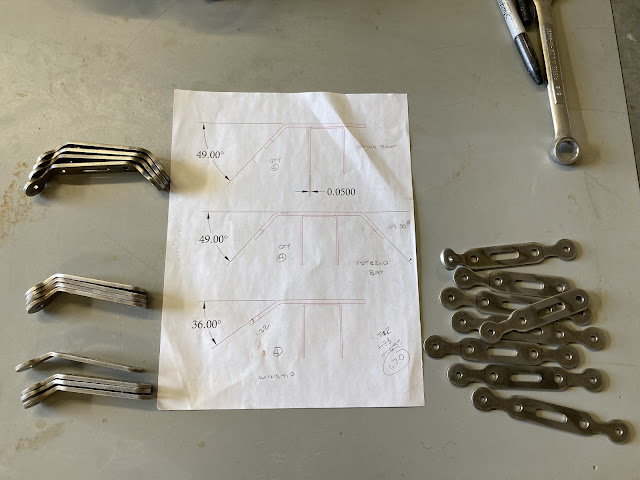

More Clipwing photos. The wing spar bushings have been turned out of 2024 aluminum bar stock. The fuel tank sender unit flanges and gas cap fittings have been made from 6061 along with all the drain fittings. I have 2 styles of gas caps. One that is vented to the air stream that will have a pressure pipe in the wind. The other one is a sealed cap that will need a check valve installed in the wing. I'm not sure which one I'll use, but I'm leaning toward the closed system with a gas door to the cap. I'll fabricate the tanks when the wing is assembled so as to get the fuel gauges centered properly in the cabin ribs. I also plan to have fuel lines to the engine run from the front and back of the fuel tanks like my Airmaster (see photo), instead of the bulbous drain fitting in the middle of the tank out in the slip stream. I also welded up the fresh air vents that are planned for the wing leading edge.