Tony Caldwell has purchased Monocoupe 90AW (Warner 145) NC15440 from Brant Seghetti. Photo credit to Will Campbell.

Tuesday, December 31, 2024

Saturday, December 21, 2024

Steve Robinson's Clip Wing Project - Part 9

As posted on the Facebook Monocoupe Aircraft Group:

Clipwing parts. Here's a photo of the master that I used to cast the new fulcrum. The original fulcrum was cast and was of a fairly low grade aluminum. My part was cast in A383 and is a stronger alloy than 6061. Casting is more than adequate for the stress that this part will be subjected to. With the bronze bushings installed there will be no noticeable wear for the load that this part will incur during normal use.

Tuesday, December 17, 2024

12-12-2024 and 12-16-2024

Crazy late fall weather here, afternoon temps in the mid 60's. We need rain though. Two great flights in the 110.

Saturday, December 14, 2024

Steve Robinson's Clip Wing Project - Part 8

More clip wing project photo's from Steve Robinson as seen on the Facebook Monocoupe Aircraft Group:

More Clipwing photos. The control stick fulcrum was badly damaged at some point. It was twisted and poorly repaired. I decided to cast a new fulcrum. I drew up a new drawing in CAD using the original print for reference and dimensions. Once in CAD, I enlarged all the dimensions by 6 percent to account for shrinkage in the foundry process. With the new dimensions I fabricated a master of the fulcrum in a proto-typing tooling material called Ren Board. Then off to the local High School that has an aluminum foundry in their metal shop. After a couple of tries, I had a good part that was then drilled for bronze bushings and finished on the outside to proper dimensions. Then bead blasted to a smooth finish.

Sunday, December 1, 2024

Steve Robinson's Clip Wing Project - Part 7

As posted on the Facebook Monocoupe Aircraft Group:

More Clipwing photos. The control sticks and assemblies were disassembled and bead blaster. The control sticks had been cut short and a 3/4 inch tube installed for a smaller diameter grip. I spliced in new 1 inch tubes for new vintage grips and machined plugs for small push-to-talk switches. The trim handle assembly was badly rust-pitted, a new lock nut was welded in and the assembly was primed and sanded a couple of times to finish out the pitting. New springs for the trim handle were sourced from McMaster Carr. The handle was sanded smooth, then nickel plated and all the small hardware cad plated.

Monday, November 25, 2024

Friday, November 22, 2024

Thursday, November 21, 2024

Steve Robinson's Clip Wing Project - Part 6

As posted on the Facebook Monocoupe Aircraft Group:

More Clipwing photos. The truth is that the very first part I purchased for my Monocoupe project was the exterior door handles! I just needed to build an airplane around them! They are hard to find and I was able to purchase 2 NOS handles in original packing! The door latch mechanisms were obtained from the doors of Cary Carson's 110 Clipwing 110SP. I was given the doors off the remains that Rick Atkins rebuilt to a new 110 using a 90A fuselage. I redesigned the latches in CAD and water jet cut the parts. One of the original latches is in the upper right corner of one of the photos (thin sheet metal). The original inner levers were used from the old doors with new bezels made of brass. All the latch parts were braised together and then the inner bezels and handles nickel plated, with the latches cad plated. All the latches are made to be bolted in place so as to be able to service them if needed. The outer door handles were keyed to be the same.

Saturday, November 16, 2024

Steve Robinson's Clip Wing Project - Part 5

As posted on the Facebook Monocoupe Aircraft Group:

Here is my latest long term project, a 1935 90A serial number 705. The fuselage will be used to build a Clipwing. It will have a Warner 165 with a new wing of 25' with 19 gallon fuel tanks and a slightly larger empennage. I have drawn the wing in CAD and have had all the wing ribs CNC cut. The nose rib cap strips have been steamed and bent to a form block and all ribs glued up.

Steve Robinson's Clip Wing Project - Part 4

As posted on the Facebook Monocoupe Aircraft Group:

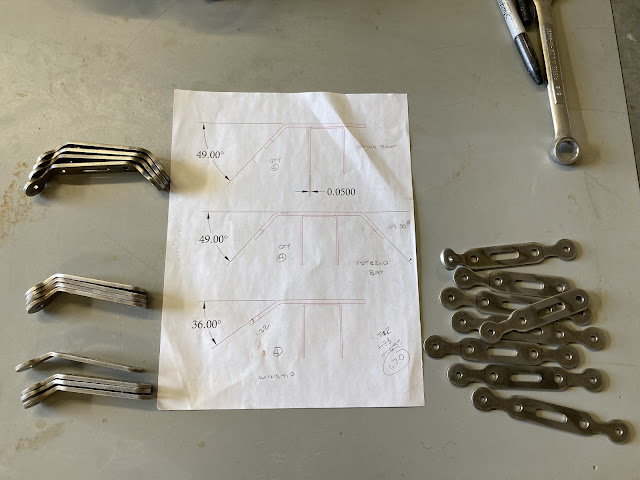

More Photos! After laying out all the parts to see what I had and what I had to fabricate, I found most of the wing hardware was either bent or badly rust pitted. I have re-drawn almost all the original Monocoupe drawings into CAD so I had all the drag anti-drag wire brackets, wing attach fittings and lift strut brackets water jet cut. I then bent them to the proper angles and welded. I cut all the drag wires to length and had the threads rolled on to each end. All parts were then cad plated.